Chemical Composition Of Cooling Water

Additives can contain eg lime phosphate or zeolite. In chemical softening various chemical combinations are added to raw water to remove hardness silica and silt from the makeup water.

Cycles Of Concentration In Cooling Water Coc

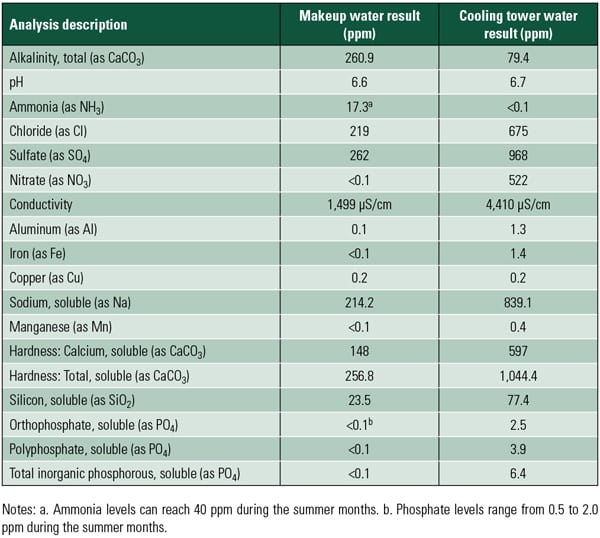

In the absence treatment there is a wide range in the relative solubility of calcium carbonate and gypsum the form of calcium sulfate normally found in cooling systems.

Chemical composition of cooling water. The type of cooling tower chemical used depends on your make up water pH and calcium levels. Outline Water Mechanical systems requiring water treatment. Heres a quick look at the major sources of cooling water fouling.

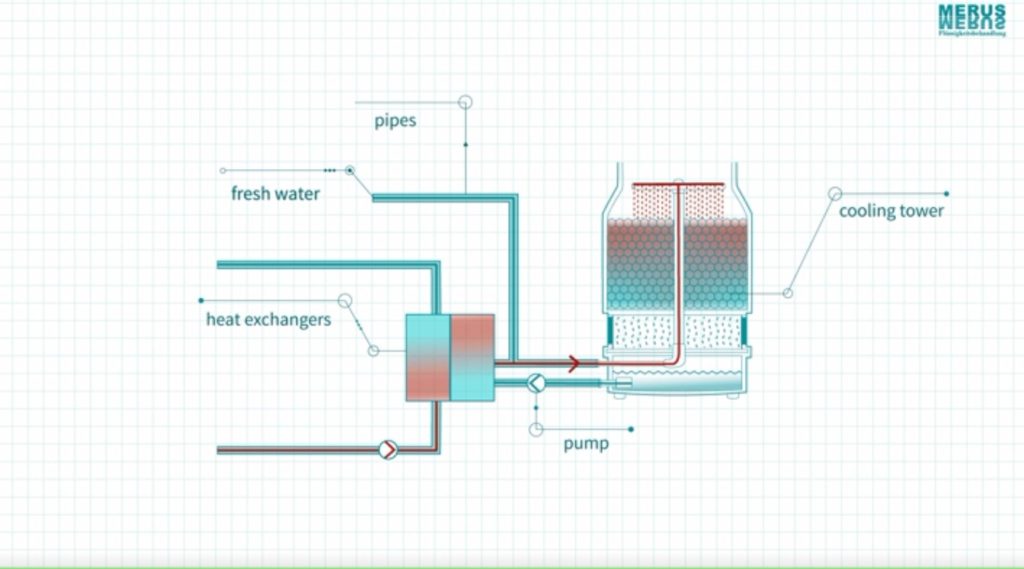

Water cooling in towers operates on the evaporative principles which are a combination of several heatmass transfer processes. Most of the cooling water additives which are approved by Wrtsil. Airborne contaminants usually consist of clay and dirt particles but can include gases such as hydrogen sulfide which forms insoluble precipitates with many metal ions.

The use of CO 2 greatly extends tool life and on most materials allows the operation to run faster. 17012018 Chemicals used in cooling tower water treatment are. In cooling water tower system bicarbonate used for corrosion inhibitors.

Recirculation The rate at which water circulates in the cooling tower in m 3 hour litressec. Chlorine bromine Hypochlorite Chlorine dioxide Ozone Non-Oxidizing Biocides. Make-Up Water Water added to the system to replace water lost through evaporation bleed of and windage.

Common cooling water issues Cooling water has many enemies. The main chemical factors which influence the tendency of cooling water to corrode are mineral salt content pH value and dissolved gases notably oxygen and carbon dioxide. Below in the cooling water systems of the engines.

Economics and boiler operating conditions dictate the technique selected for the application. Are nitrite typically NaNO2 based and today the majority of the installations in operation are also using nitrite based additives. For example algae growth creates the perfect environment for corrosion to take hold.

Sometimes they work alone. Scale and scalelike deposits include calcium. The significance of DOM and the presence of an iron hydroxide layer was investigated.

Cooling Tower Water Treatment Principles. There is a slow trend towards more environmentally friendly alternatives. Advisable to use biocides in the cooling water treatment two classes.

The circulating water for the cooling tower should be filtered for removing particulate matter and to be dosed with microbiocides for the prevention of biological growth in addition to treating circulating cooling water for the reduction of scaling and fouling in large industrial cooling tower systems. Normal Composition Results in fuel loss of 2 Savings Price of energy - 800MMBtu. Bicarbonate as known as Hydrogen Carbonate is a chemical compound with HCO3- formula.

Cooling Tower Chemicals deal with the treatment of cooling tower circulating water. An antifreezecoolant composition comprising a glycol as the main ingredient about 01-80 by weight of at least one ingredient selected from the group consisting of C 6 -C 12 aliphatic dibasic acid and alkali metal salts thereof and about 01-10 by weight of at least one ingredient selected from the group consisting of p-toluic acid and alkali metal salts thereof. We can usually find bicarbonate commonly in sodium bicarbonate form which is in baking soda.

562 Appendix E Cooling Water Calculations amount of foreign matter depends upon the water source and the surrounding environment. Chemical Treatment of water for Cooling and Heating Systems Prepared and Presented by. Calcium carbonate scaling can be predicted qualitatively by the Langelier.

CO 2 can provide controlled cooling at the cutting interface such that the cutting tool and the workpiece are held at ambient temperatures. The most important of these is the transfer of liquid into a vapourair mixture as for example the surface area of a droplet of water. In other instances they team up and compound the problem.

A steel corrosion inhibitor selected from one of from 06 to 60 by weight of a phosphono-carboxylic acid from 16 to 165 by weight of a water-soluble molybdate salt and sufficient water-soluble zinc salt to give a zinc. Methylene-bis-thiocyanate MBT Organotin compounds Aldehydes Chlorophenols Sulphones and Thiones Carbamates Isothiazoline. In recarbonated cooling water if the DOM is doubled the amount of calcite predicted to precipitate is decreased by 125 and the.

The DOM suppresses the precipitation of calcite eg. Also their soluble and insoluble hydroxide forms can each cause precipitation of some water treatment chemicals such as orthophosphate. The present relatively stable water treatment composition characterised in that it comprises from 01 to 10 by weight of an azole copper corrosion inhibitor.

Bleed Off Water deliberately bled from the system to prevent the cooling system water from becoming too concentrated. Knowing these two factors will determine the cooling tower chemical blend required to minimize corrosion andor scaling. Carbon Dioxide chemical formula is CO 2 - is used as a coolant replacement for cutting fluids.

The cooling tower is an efficient scrubber of suspended particulates plus gases such as carbon dioxide C0 2 sulfur dioxide S0 2 and ammonia NH 3 from the atmosphere.

Pin On Coating And Lining Division

New Learner Basics Cooling Tower Water Treatment Power Engineering

Chemical Composition Of Cooling Water 2 Download Table

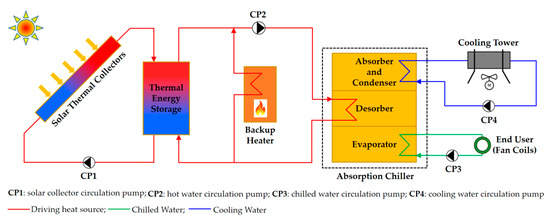

Applied Sciences Free Full Text New Developments And Progress In Absorption Chillers For Solar Cooling Applications Html

Performance Based Cooling Water Treatment

Arc Furnace Manufacturers In 2021 Furnace Electric Furnace Electricity

Schematic Of A Direct Evaporative Cooling System Download Scientific Diagram

Post a Comment for "Chemical Composition Of Cooling Water"