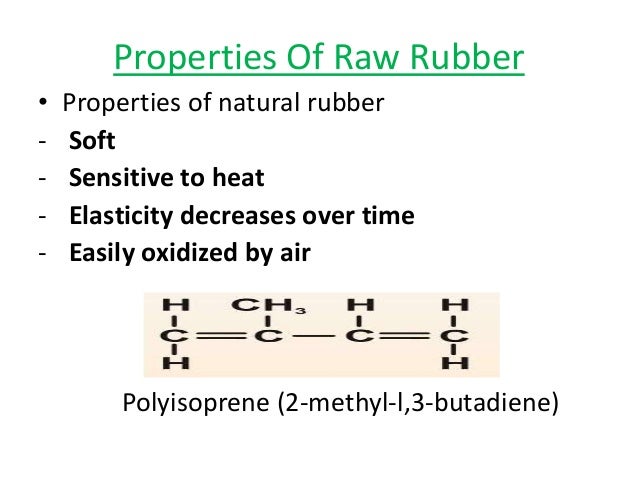

16122020 Natural rubber is a polymer of isoprene also known as 2-methylbuta-13-diene with the chemical formula C 5 H 8n. Experience has also shown that metallic salts of zinc or lead and especially certain organic compounds called accelerators greatly affect the rate of vulcanization and these are favorably employed in.

Difference Between Vulcanized And Unvulcanized Rubber Properties Process Of Vulcanization

2 Classification Based on Structure of Polymers.

Chemical formula of vulcanized rubber. These polymers formed by chemical reaction in a controlled environment and are of commercial importance. 20112017 Over the next several years Goodyear successfully recreated the chemical formula and perfected the process of blending sulfur and rubber at a high temperature patenting it in 1844. Low water absorption tendency.

SBR is a product of synthetic rubber research that took place in Europe and the United States under the impetus of natural rubber shortages. Vulcanized Rubber is an improved form of Natural. Typical ranges are between 14 to 50 percent acrylonitrile.

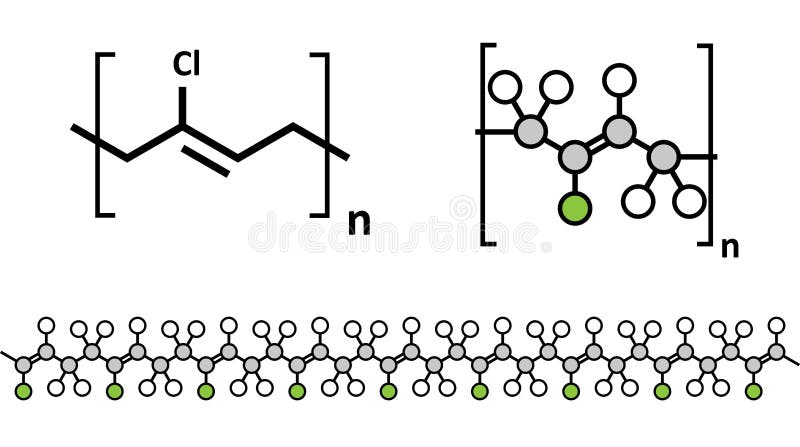

In fact chloroprene is one of the few rubbers that are self-extinguishing. To put it more simply its made of many thousands of basic C 5 H 8 units the monomer of isoprene loosely joined to make long tangled chains. The second main component is Vulcanized Rubber.

The amount of Acrylonitrile is varied to provide different range of oil resistance the base polymer will have. In naming this process he chose to call his discovery vulcanization after the. To increase the cure rate.

Butyl rubber is copolymerized from isobutylene which is methylpropene H 2 CC CH 3 2 and a small percentage of isoprene. 24022015 NBR is the polymerization of Acrylonitrile CH 2CHCN and Butadiene CH2CH-CHCH2 into one large multiple-unit chains. HALO BUTYL CHLORO BUTYL.

This works partly because of the mixture of sulfur into the rubber. The new or vulcanized rubber obtained has properties that are just opposite to that of natural rubber. Zinc oxide ZnO 8138 gmol analytical purity VETEC stearic acid CH 3 CH 2 16 COOH 28448 gmol analytical purity VETEC mercaptobenzotiazol S 2 NC 7 H 5 16725 gmol analytical purity ORGANIC sulphur S 8 25652 gmol analytical purity VETEC.

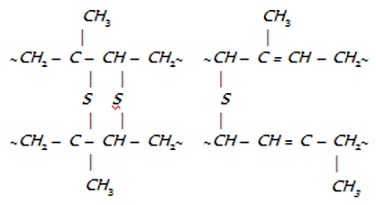

01022016 Start reagents chemical formula purity and origin of the vulcanized system utilized were. Vulcanized rubber has excellent elasticity. The cross-linking reaction between sulfur and rubber occurs mainly at the carbon-carbon double bonds CC in large excess of sulfur.

Tires are made out of a product known as vulcanized rubber. Vulcanized Rubber Sulphur is used in cross bonding the polymer chains found in natural rubber Cellulose acetate rayon etc. A tiny amount is used for bubble-gum in the unvulcanized form.

To improve the reversion resistance of the Butyl Rubber and the co-vulcanisation with other diene rubbers butyl rubber is halogenated with Chlorine and Bromine to get CHLOROBUTYL RUBBER. Learn different types of Polymerization here. These additives modify the polymer by forming cross-links bridges between individual polymer chains.

Often accelerators are added to speed up the vulcanization and to reduce the amount of free sulfur which has a detrimental effect on. It is resistant to attack of oxidizing agents. It also gives excellent rubber-to-metal bonds.

100 phr of dry natural rubber was mixed with an activation system made up of 4 phr of zinc oxide and 3 phr of stearic acid. Vulcanization is a chemical process for converting natural rubber or related polymers into more durable materials via the addition of sulphur or other equivalent curatives or accelerators. Its chemical formula is C5H8.

However chloroprene tends to harden over time and degrades in the presence of some fairly common chemicals such as hydrochloric acid acetone xylene acetic acid and hydrogen peroxide. Nitrile rubber is copolymerized from butadiene and acrylonitrile H 2 CCH-CN. This is one of the chemicals present in most types of tires while others are only used when making specific tire types.

This material can be used in place of polyurethane in some shoes. It is resistant to the action of organic solvents. The vulcanization process is what makes the tires hard and heat resistant.

Extensive investigation has revealed other substances such as benzoyl peroxide or polynitrobenzenes which can transform rubber into a vulcanized condition. SBR is a mixture of approximately 75 percent butadiene CH 2 CH-CHCH 2 and 25 percent styrene CH 2 CHC 6 H 5.

Theoretical Explanation Of Vulcanisation Of Latex Of Landolphia Owariensis P Beauv Using Sodium Sulphite Na Sub 2 Sub So Sub 3 Sub Solution Under Low Temperature

Vulcanization Mechanism Of Natural Rubber

What Is The Monomer Of Natural Rubber A Plus Topper

Learn Natural Rubber Vulcanization Of Natural Rubber Meaning Concepts Formulas Through Study Material Notes Embibe Com

Synthetic Rubber Stock Illustrations 498 Synthetic Rubber Stock Illustrations Vectors Clipart Dreamstime

Halo Butyl Rubber Pricing Supply conditions in the USA improved as operating efficiency at several manufacturing units including Eastman Chemicals and Goodyear Tire and Rubber Co. ramped up after the devastating impact from the winter storm Uri. However, some constraints were witnessed as few manufacturing plants in the US Gulf Coast region still struggled to operate at normal rates, and the offtakes from the pharmaceutical equipment were consistent to meet the demand of the mass vaccination drives in the US. Demand surged in the second quarter of 2021, due to the improved offtakes from the tire industry and export market outlook as the production levels regained pace

ReplyDeletehttps://www.chemanalyst.com/Pricing-data/halo-butyl-rubber-1112