Glass-lining is one of the best ways that aptly serves the purpose due to its insuperable characteristics and exclusive nature. These reactors include an integral baffle which improves the carrying out of such reactions without sacrificing advantages resulting from use of such equipment.

China Manufacturer Of Pharmaceutical Glass Lined Reactor Enamel Reaction Tank China Glass Lined Reactor Enamel Reaction Tank

High chemical stability of PTFE good mechanical properties and permanent resistance in atmosphere humidity gasses and temperature changes results in suitabili-ty of TF34 system for all type of glass lined reactors and different aggressive chemicals.

Chemical composition of glass lined reactor. De Dietrich glass-lined reactors have been at the heart of chemical operations for over a century. De Dietrich Process Systems can provide glass-lined reactors to meet a wide variety of chemical processes volume requirements from laboratory scale and pilot plant sizes up to very large production units incorporating local design and international code requirements ASME AD2000 GB150 JIS Thanks to the properties of our enamel DD3009. Quality on stainless steel.

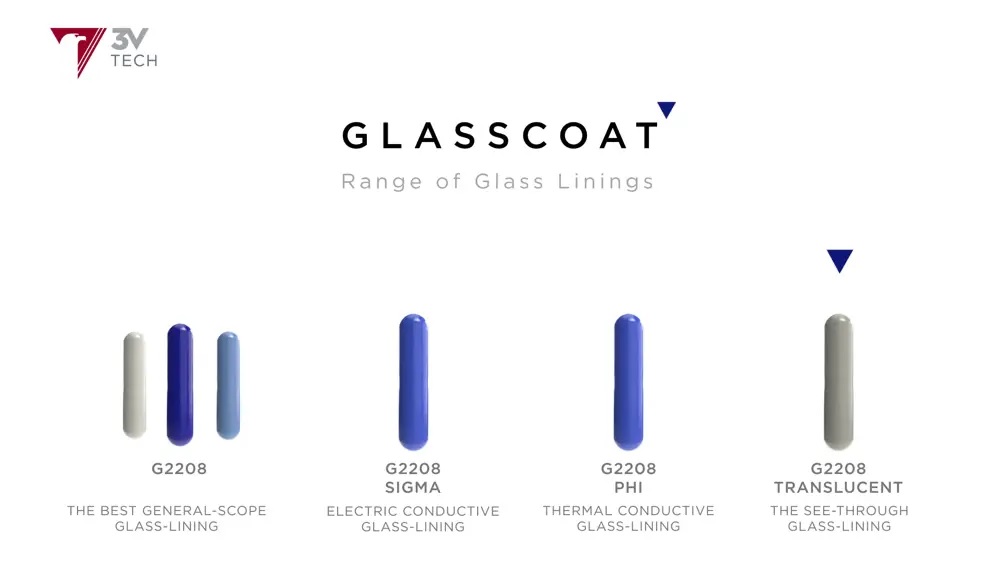

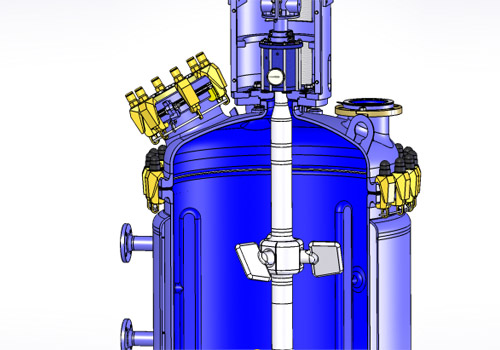

Reactors are glass lined with premium highly acid corrosion resistant glass G2208 available in blue light blue white and TransLucent 100 metal free for HAPI and heavy chemical duty. When in doubt consult our Bulletin 3009 Glass or De Dietrich to confirm the use of glass-lined steel for your application. BE type reactors are equipped with PressLock radial and axial stirrers solutions available for high viscosity multi-purpose API reactors gas dispersion solid suspension and high turbulence.

And in that a thin lining of glass is provided which is made up of Borosilicate glass. The typically carbon-steel shell is designed and built to ASME code and then lined internally with our proprietary 3009 Glass. Starting from 4 litres up to 80000 litres in which the reactive media is loaded and processed.

26052021 Reactors are made up of glass that has borosilicate as a major component to handle acidic reactions known as Glass Lined Reactors. De Dietrich Glass-Lined Reactors. A reactors glass lining may be eroded by abrasive solids in the reactants.

Basically there are three applications where glass-lined equipment is used. Composition of this glassy layer depends on the kind of chemical resistance desired and the temperatures used during reactions in the reactor. Glass and steel together offer chemical inertness and absence of catalytic effect and contamination at higher operational temperature and pressure.

01072007 What allows glass-lined steel to be used with most corrosive materials is the slow rate of reaction. No thin spots no bare metal no exposed base coat - all of which can occur with other glasses. Glass lined Reactors GLRs have a glass enamel coating on the product wetted surfaces to provide high levels of chemical resistance to said surfaces.

In addition all accessories used must be compatible with the process. Acids alkalis and even water can corrode glass. The exception to this is phosphoric acid in which the speed of attack increases with the concentration.

The Lined word shows the application of glass lining inside the stainless steel reactor to handle strong acids. The glass lining will withstand a wide variety of chemical reactants. These technologies are critical to the safe containment of corrosive contents maintaining the vessel pressure and ensuring the final batch quality.

Glass lined reactors for use with chemical reactions which require special conditions such as high temperatures or temperature control. Its called Glasteel. 17102020 The outer body of the reactor is mostly made up of MSCS etc.

These are robustly designed and manufactured to stand up to very harsh environments. 01 mmyear at 163C for 10 concentration and at 112C for 70 concentration. A glass-lined inner vessel.

A glass lined reactor is a metallic reactor coated with a chemical resistant layer of glassy material. The attack rate is determined by temperature duration and the concentration of reagents. One reason why our glass-lined equipment is trusted by over 90 of the worlds top chemical companies is the sheer reliability of our reaction technologies and comprehensiveness of our glass-lined accessories.

Check the chemical resistance of all components and proceed accordingly. After decades of effort Pfaudler researchers have developed a new glass formulation along with special application. Calcium Magnesium Silicon and Boron are essential elements of the composition.

Hydrofl uoric acid completely and quickly dissolves the glass whatever the temperature is. Provided is a cover coating composition for a glass lining comprising a frit constituting the composition which mainly includes 65 to 75 mol of SiO 2 2 to 8 mol of ZrO 2 10 to 22 mol. The inner thickness provided of glass mostly ranges from 11mm to 22mm only.

Glasscoat offers reactors for hydrogenation cryogenic reactions and reactors. It is the first high-voltage test glass that can be applied and tested to guarantee a reliable glass lining of uniform thickness. The glass coating is sprayed then fused onto the surface of sub-straight material at high temperature in a repetitive process until the desired glass thickness is achieved.

Stainless Steel Reactors Glasslined Reactors in Stainless steel construction with highly polished exteriors to meet stringent cGMP and FDA requirements. Composition of a typical glass-lined reactor Typically a glass-lined reactor whether DIN standard or customized consists of. 4000 imported form Pfaudler USA we can now offer a reliable glass lining of uniform thickness and quality on stainless steel.

Enveloped with PTFE and open on one side usually on the outside. Our Stainless steel glasslined reactors are suitable for cryogenic processes pure products.

Glass Reactor Double Single 50l Jacketed Glass Reactors Wkie Lab

Glass Lined Reactor Glass Lined Vessel 3v Tech Glasscoat Ireland

A Study On The Development Of Refractories For Carbon Black Reactor Manualzz

How Are Glass Lined Vessels Made

The Benefits Of Glass And Glass Lined Steel Reactors

Countinus Stirred Reactors Autoclaves Stir Market Research

R D On Commercial High Temperature Gas Cooled Reactor Sciencedirect

Glass Lined Reactor Glass Reactor Monobloc Agitators By De Dietrich

0 comments:

Post a Comment