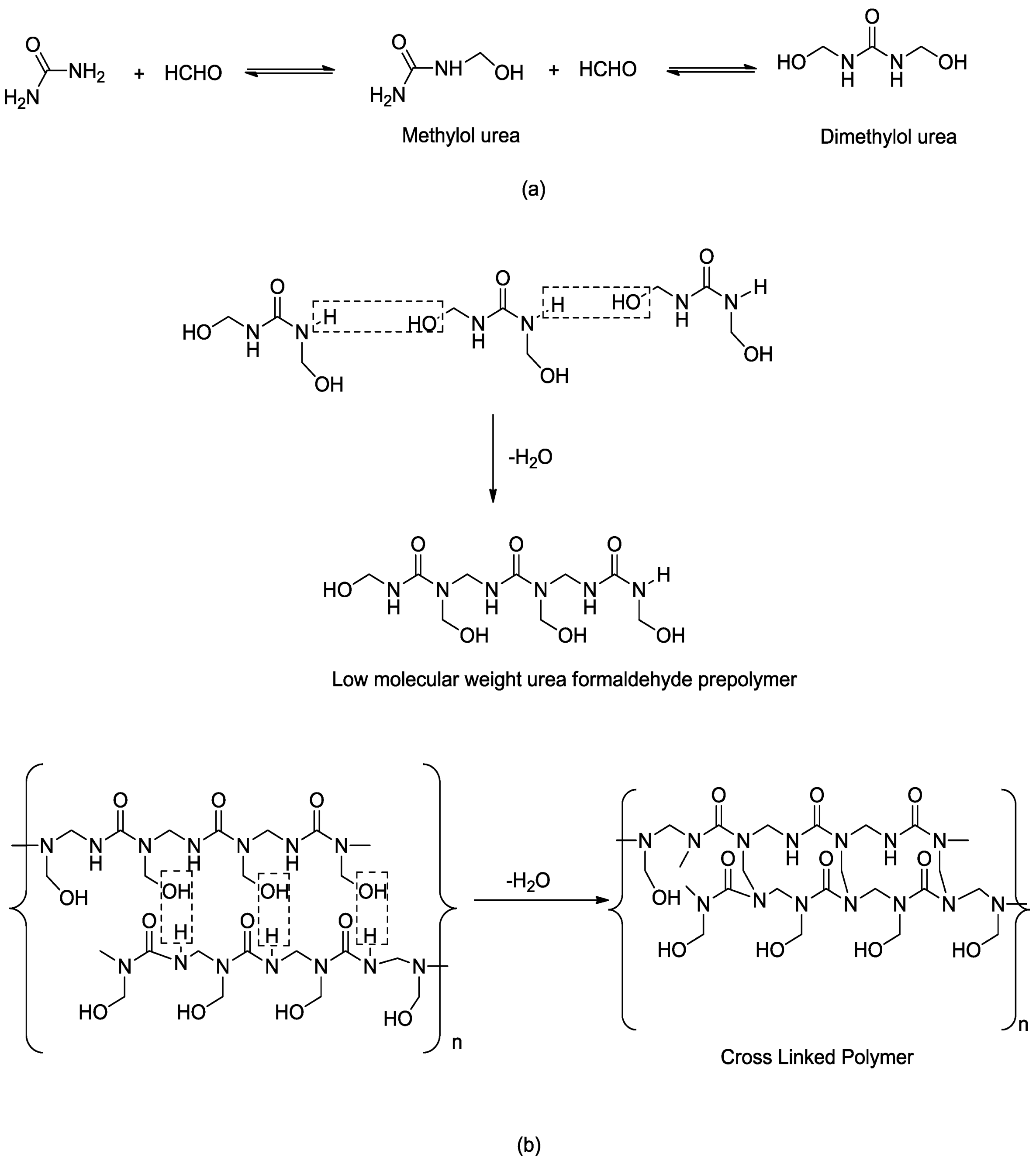

Structure and general properties of Urea-formaldehyde. The condensation reaction gives a colourless syrupy solution that can be spray-dried to a powder for later use in coatings or adhesives.

Synthesis Steps Of Urea Formaldehyde Resins Download Scientific Diagram

Urea-formaldehyde UF products also called aminoplasts are highly crosslinked semi-crystalline thermosetting plastics.

Chemical equation for preparation of urea formaldehyde resin. Preparation of urea-formaldehyde resin comprises ureaformaldehyde condensation carried out in presence of ammonia at pH varying from 71-715 to 51-53 at 88-104C atmosphere pressure and ureaformaldehydeammonia molar ratio 120-2201-013 until viscosity using viscosimeter VS-4 achieves 155-260 s after which. UF resins are among the. Infact they are some of the fastest curing resins available.

Properties of urea-formaldehyde is given in detailed. CHEMISTRY INVESTIGATORY 2 PROJECT Formation and structure Urea-formaldehyde resins as a group are formed by a step-growth polymerization reaction that can be either acid- or base-catalyzed. It can also be mixed with cellulose filler to produce powders for molding into solid.

The UF-resin itself is formed in the acid condensation step where the same high molar ratio as in the alkaline methylolation step is used FU 18 to 25. Phenol formaldehyde urea formaldehyde and melamine formaldehyde and also as disinfectant and as preservative for biological species 17 28. Urea-Formaldehyde Resins Urea-methanal Properties.

Urea is reactive towards formaldehyde at the ortho and para sites sites 2 4 and 6 allowing up to 3 units of formaldehyde to attach to the ring. The cheaper grades are sometimes lower in weight cost than the general purpose. Isopropylbenzene is formed as an intermediate in the Hock process by a Friedel.

Urea formaldehyde UF resin which is one of the most important wood adhesives is a polymeric condensation product of the chemical reaction of formaldehyde with urea and considered as the most important ype of adhesive resins for the production of particleboards. Urea-formaldehyde resins which may be cured to give products having a low total extractable formaldehyde content are prepared by the following process. Chemicals-Urea formaldehyde sol conc.

AIM- To prepare urea formaldehyde resin. Urea has a molecular weight of 6006gm. C iii a mineral or organic acid is added to.

Apparatus required-Beaker glass rod funnel filter paper and chemical balance. Theory-Amino resins are condensation products obtained by the reaction of formaldehyde with. The methylolureas urea and the residual free formaldehyde react to form linear and partly branched molecules with medium and even higher molar masses forming polydispersed UF-resins composed of oligomers and polymers of.

The structure of Pre-Condensate is a short-chain molecule combined with CH2 bridges. The UF resins are noted for their high strength rigidity cost effectiveness and fast cure. The present study is aimed to preparation and characterization of urea.

Apart from the main reaction above there are several side reactions producing several by-products of dimethyl ether formic acid carbon monoxide and carbon dioxide. It has a wide color range. Procedure Low methanol-37 formalin 2840 g 35 mol Note 1 2 g of 80 triethanolamine and urea 1133 g 189 mol are charged with agitation into a 5 L three-necked flask equipped with stirrer reflux condenser and thermometer.

Urea-Formaldehyde Resin Submitted by. In industrial production urea resins are made by the condensation of formaldehyde and urea in an aqueous solution using ammonia as an alkaline catalyst. I an aqueous solution containing more than 50 formaldehyde and urea are mixed in a formaldehydeurea molar ratio of 2-31 at pH 6-11 ii this mixture is heated to at least 80.

11072020 September 16 2020. The UF resins are noted for their high strength rigidity cost effectiveness and fast cure. The main product from the formaldehyde reactor is formaldehyde produce as follows.

The International Agency for Research on Cancer IARC 29 in 1987 and in 2006 has classified formaldehyde as a probable human carcinogen. 13102009 The Chemical formula of Urea is CONH22 its empirical formula is just the same as its chemical formula. Synthesis of formaldehyde from methanol.

Urea-formaldehyde UF products also called aminoplasts or carbamide-methanal are highly crosslinked semi-crystalline thermosetting plastics 1. 2CH3OH O2 2HCHO H2O This reaction is highly exothermic. Urea-formaldehyde resins can be cured with isopropylbenzene production wastes containing 200-300 gl 1 of AlCl 3 as an acid hardener 50.

Which is the product of a condensation reaction between urea and formaldehyde 1. A process for the preparation of urea-formaldehyde resins which comprises i mixing an aqueous formaldehyde solution containing more than 50 by weight of formaldehyde with urea at a formaldehydeurea molar ratio of 2 to 31 and at pH 6-11 ii heating the mixture to at least 80.

Liquid Urea Formaldehyde Resin Manufacturing Industry Youtube

Urea Formaldehyde Resins An Overview Sciencedirect Topics

Structure And Properties Of Urea Formaldehyde Resin Polyurethane Blend Prepared Via In Situ Polymerization Rsc Advances Rsc Publishing Doi 10 1039 C5ra06029j

Materials Free Full Text Development Of Self Healing Coatings Based On Linseed Oil As Autonomous Repairing Agent For Corrosion Resistance Html

Pdf Effect Of Different Catalysts On Urea Formaldehyde Resin Synthesis Semantic Scholar

Pdf Effect Of Different Catalysts On Urea Formaldehyde Resin Synthesis Semantic Scholar

Figure 1 From Hydroxymethyl Furfural Modified Urea Formaldehyde Resin Synthesis And Properties Semantic Scholar

0 comments:

Post a Comment