Density and strengths can be controlled to meet specific structural and. The UHSC formulation.

Design Specification For Ultra High Strength Concrete Concrete Show Blog

01012016 Ultra high strength concrete UHSC is one of the most spectacular developments of recent years in the area of Portland cement-based materials.

Chemical formula of ultra high strength concrete. It is used in buildings roads bridges and dams. This is a complex process that is best understood by first understanding the chemical composition of cement. Higher strengths can be produced with the addition of supplementary cementitious materials.

Concrete is actually a mixture of cement the binder water and some form of aggregate the filler. The process is known as hydration. 30032015 HIGH STRENGHT CONCRETE.

They are blended with fibers in order to achieve ductile behavior under tension which may eliminate the need for passive non-prestressed reinforcement. Nano Silica Concrete incorporates nano silica instead of micro silica particles or well known silica fumes. High-strength concrete has a compressive strength greater than 40 MPa.

Compound Phase Chemical Formula Notation Range. The most interesting finding is tensile and flexural enhancement of mortar containing nano metakaolin is around 1015 as compared to plain OPC 86 87. It achieves this engineering feat by progressively absorbing the energy.

Due to low wc ratio it causes problem of placing to overcome from this superplasticizer used. Materials for High-Strength Concrete. Grouting in concrete and masonry structures is one of.

When selecting aggregates for high-strength concrete producers consider the strength of the aggregate the optimum size of the aggregate the bond between the cement paste and the aggregate and the surface characteristics of the aggregate. Almost any ASTM portland cement type can be used to obtain concrete with compresive strength. Introduction Portland cement gets its strength from chemical reactions between the cement and water.

It is known for its high compressive strength and versatility which makes it an ideal material for the basis of most structures. Reference High Strength Flowing Concrete Cement Reduced Mix Cement 356 356 356 267 Sand 712 742 772 845 Stone 1127 1216 1068 1187 Water 178 133 178 133 Superplasticizer lm3 - 09 09 06. Retarding admixtures consists of both organic and inorganic agents.

High strength concrete is made by lowering the water cement WC ratio to 035 or lower. This concrete results in higher initial and final compressive strengths higher workability and lower permeability. Appropriate batching casting finishing and curing procedures are of the utmost importance in order to ensure the highest level of.

Nano metakaolin addition in concrete has improved the strength of mortar where almost 810 increment of compressive strength can be achieved. Final strength is achieved by maximum water reduction which needs ultra-strong dispersant molecules adds Hbsch. UHSC is composed of cement fine sand quartz powder micro silica HRWRA high range water reducer admixture and steel fibers optional to increase its concrete ductility and tensile strength.

Compounds in Cement and Their Influence on Concrete Strength Tricalcium silicate and Dicalcium silicate The chemical formula for Tricalcium silicate C 3 S and Tricalcium silicate C 3 S are 3CaOSiO 2 and 2CaOSiO 2 respectively. Additionally higher tensile strength. 30102014 As per chemical admixture classification by ASTM-ASTM C 494 type B is simply a retarding admixture while type D is both retarding and water reducing resulting in concrete with greater compressive strength because of the lower water-cement ratio.

To make ultra-high strength concrete you need very strong plasticisers. 04032019 Concrete is an important part of modern infrastructure. HIGH-PERFORMANCE CELLULAR CONCRETE High-Performance Cellular Concrete HPCC has all the properties of cellular concrete and can achieve 5537 MPa 8000 psi.

Characteristics of Ductal. Is fiber-reinforced and has tensile strength unlike conventional concrete. The chemistry is cutting edge while still embracing the natural qualities of concrete.

Any of these properties could limit the ultimate strength of high-strength concrete. The UHPC possesses unprecedented flexural strength allowing for finer thinner lighter and more elegant designs. Wherever the high strength is required the elastic modulus of the material should be higher.

PROPERTIES OF ULTRA HIGH STRENGTH CONCRETE INCORPORATING NANO-SILICA Author. The absence of coarse aggregate is considered by the inventors to be a key-aspect for the microstructure and the performance of the UHSC. Two silicates namely C 3 S and C 2 S control most of the strength giving properties.

15022017 In a report by Morsy et al. Initially this new type of concrete developed by Pierre Richard the former scientific director of the French Bouygues Company was known as reactive powder concrete RPC Richard and Cheyrezy 1994. Compressive strength of 17000 psi 117 MPa after 28 days.

May be based on many different chemical reactions involving different binders such as Portland and non-Portland cements sodium silicate sodium aluminates.

Tensile Strength Of Concrete At 28 Days Download Table

Effect Of Fc3r On The Properties Of Ultra High Performance Concrete With Recycled Glass

Materials Free Full Text Early Age Strength Of Ultra High Performance Concrete In Various Curing Conditions Html

Structure Magazine Ultra High Performance Concrete

Mixing Design And Microstructure Of Ultra High Strength Concrete With Manufactured Sand Sciencedirect

Ultra High Performance Concrete An Overview Sciencedirect Topics

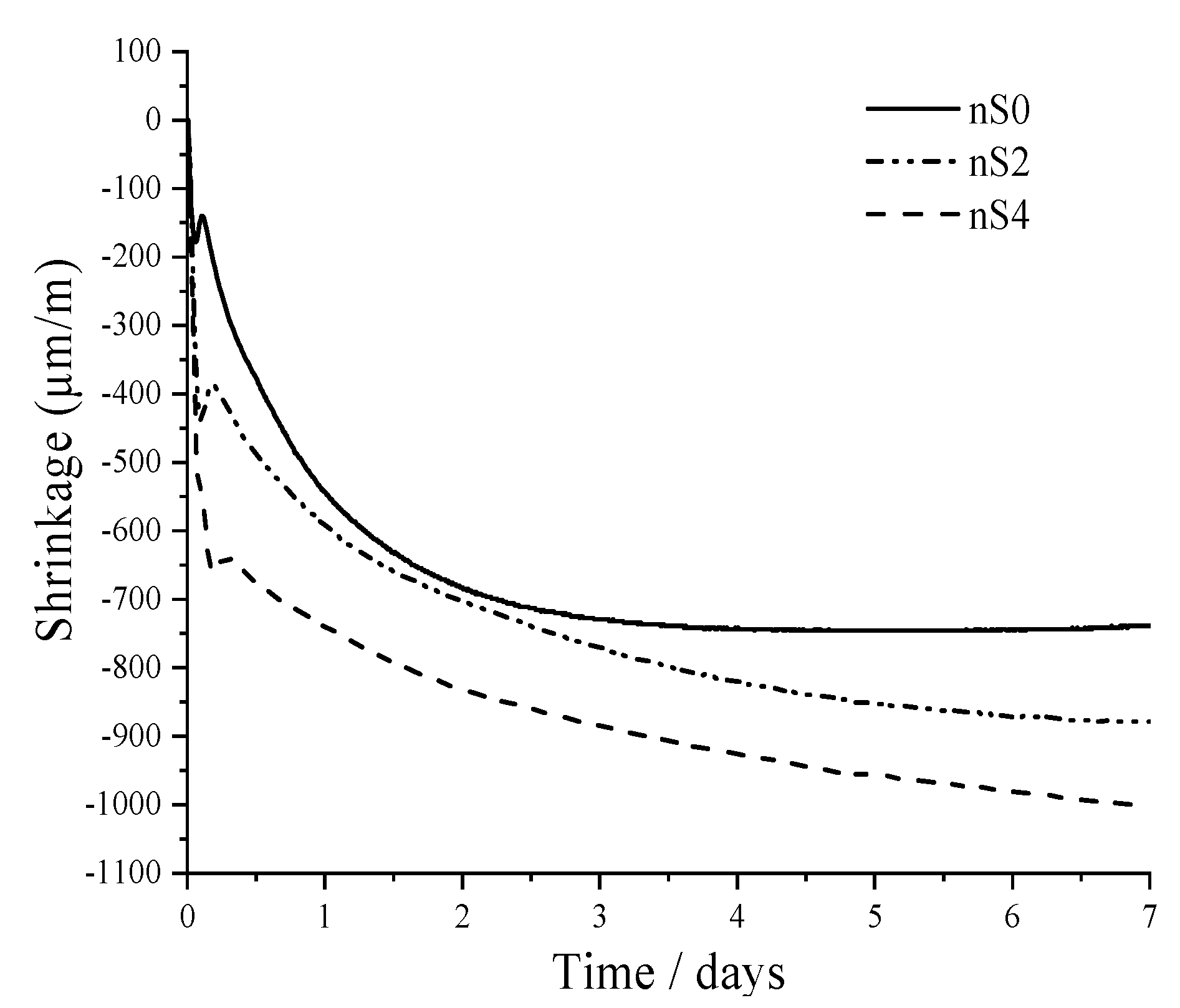

Applied Sciences Free Full Text Effect Of Nano Silica On The Autogenous Shrinkage Strength And Hydration Heat Of Ultra High Strength Concrete Html

Mixing Design And Microstructure Of Ultra High Strength Concrete With Manufactured Sand Sciencedirect

0 comments:

Post a Comment