Carbon is at the same time one of the softest graphite and hardest diamond materials found in nature. This polymer is stretched so that it lines parallel to the axis of the fibre.

What Is Carbon Fiber How Is It Made And Is It Indestructible

Chemical Composition of Keratin.

Chemical formula of the material carbon fiber. 15082019 The term carbon fiber refers to organic materials that have been heat-treated at temperatures of 10003000C and generally contain 929999 carbon. Carbon fiber is a important textile fiber. 3 while the density of natural graphite is 225 gmcm.

The number of electrons in each of Carbons shells is 2 4 and its electron configuration is He 2s 2 2p 2. By heating this newly treated polymer to a further 2500 degrees in a nitrogen rich environment the polymer is then. Carbon-fibre reinforced composite is the common form of composite used today.

It was continued up to 1907. Oxygen can be as O2 or as O3 the latter called oxygen. Examples of composite materials include fibre-reinforced polymer carbon-fibre-reinforced composites and ceramic composites among others.

Keratin contains sulpher for this reason it is very easy to separate keratin from the other elements. In its elemental form carbons CAS number is 7440-44-0. Carbon Fiber will be a big part of my life because 3D printers are able to print things in different materials such as Carbon Fiber.

Carbon fiber is the oldest types of manmade fiber. Graphite is a crystalline material in which the sheets are stacked parallel to one another in regular fashion. Chemical composition of keratin is given below.

Fibers made from natural and synthetic organic polymers. Carbon is also used for non-flame able cloth manufacturing. Carbon fibers have been found to be around 341 to 347 X 1321.

In the modern times carbon fiber is used in cover of aircraft space rocket. Depending on the type of raw material chemical fibers are divided into synthetic from synthetic polymers and natural from natural polymers categories. Fibers prepared from inorganic compounds glass metal basalt or quartz are sometimes also regarded as chemical fibers.

About 90 of the carbon fibers produced are made from polyacrylonitrile. Graphite fiber refers to carbon fiber precursors that have been processed at temperatures exceeding 2500C for an extended period of time. Carbon fiber was used as the filament of lamp in 1880.

30052017 Carbon fibers from polyacrylonitrile PAN. The remaining 10 are made from rayon or petroleum pitch. Carbon fibre is made up of the polymer PAN.

As a result of these properties carbon fibers are useful reinforcements in composite materials. Commercially available carbon fibers possess high tensile strength 37 GPa high tensile modulus 200935 GPa compressive strength 13 GPa and compressive modulus 100300 GPa as well as low density 175220 gcm 3. The density of carbon fibers ranges from 15 to 20 gmcm.

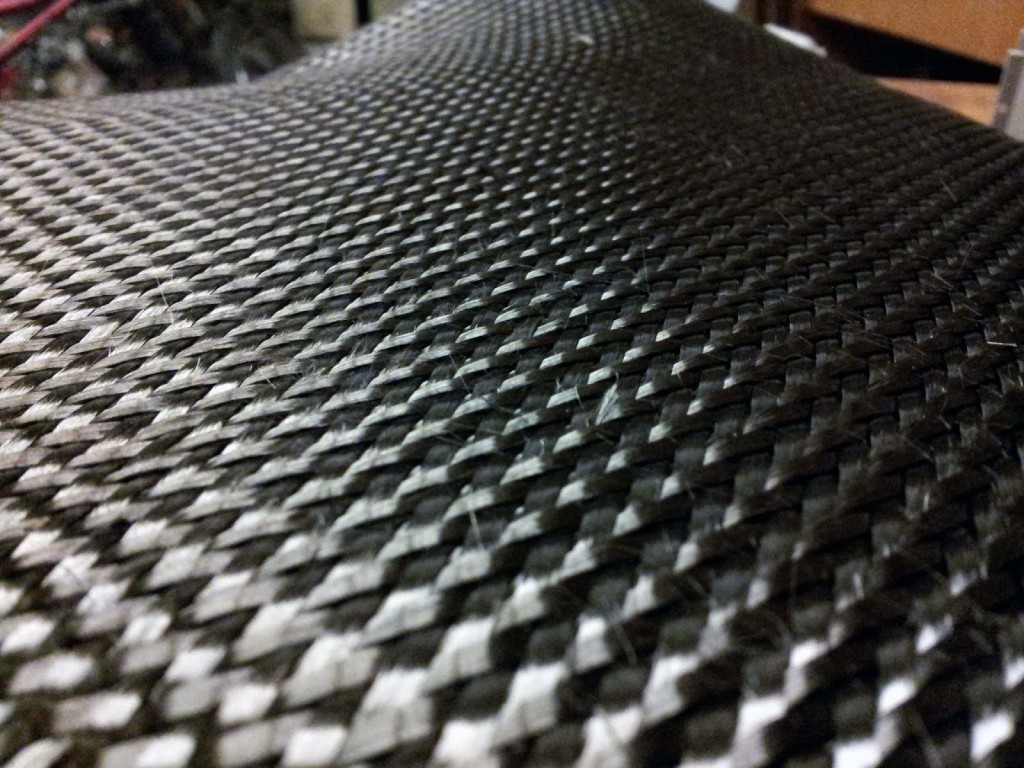

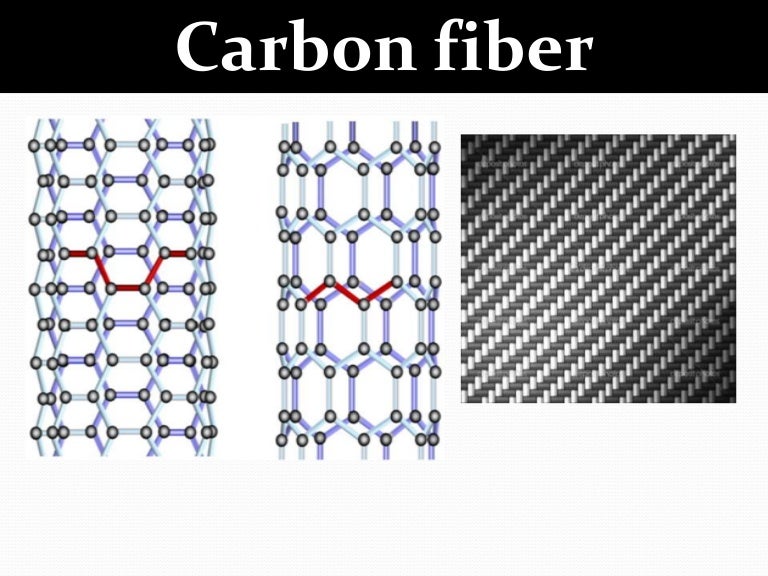

Carbon fiber alternately called graphite fiber is a polymer made from another polymer called polyacrylonitrile by a complicated heating process which is a form of graphite material consisting of extremely thin fibers about 0005-0010 mm in diameter and composed mostly of carbon atoms. 3 and that of pyrolytic. Many elements have more than one pure form.

Carbon fibers carbon nanotubes and many other nano-technology substances as well as diamonds and graphite all have the formula C. 13112014 The atomic structure of carbon fiber is similar to that of graphite consisting of sheets of carbon atoms graphene sheets arranged in a regular hexagonal pattern the difference being in the way these sheets interlock. At first Carbon fiber was invented in 1850.

These values can be compared to values of 335 A for natural graphite. The polymer is the oxidised at 200-300 degrees to remove the Hydrogen and add Oxygen to the molecule. Carbon is insoluble all the time.

This is because it is impossible to know how many atoms are in a piece of a pure element. For the purposes of this report however graphite fibers will not be distinguished from carbon fibers. 09102014 Currently the use of carbon fibers and their composites in space and aerospace applications continues to grow.

The carbon atoms are bonded together in. In this chapter a brief explanation of various processing methods will be provided and the manufacturing. However the vast majority of composite molding is used in automotive marine industrial and recreational applications.

The exact composition depends upon the position of the material in the fiber and the treatment to which it has been subjected. The raw material used to make carbon fiber is called the precursor.

Carbon Fiber Structure And Properties Carbosystem

0 comments:

Post a Comment